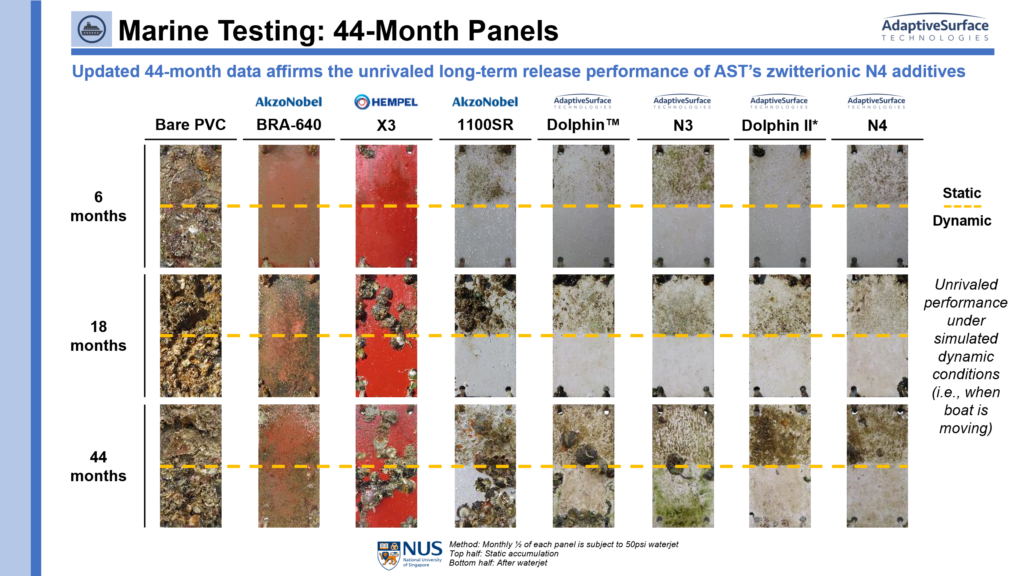

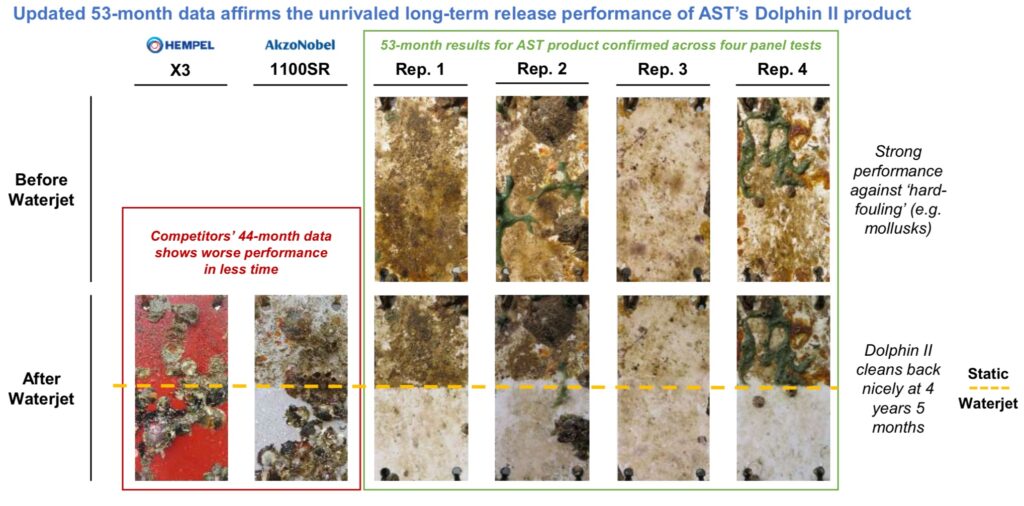

HOPKINTON, Mass. – September 19, 2024 – Adaptive Surface Technologies (AST), a leader in repellent surfaces, today announced new long-term performance data for its SLIPS Dolphin™ II marine anti-fouling coating and N4 additive product. Dolphin II and N4 have been subjected to 53 months of exposure testing, led by an international third-party, and both outperformed the leading commercial foul-release coatings on the market.

When submerged in water, Dolphin II creates an ultra-smooth, slippery surface that prevents organisms from attaching. The product lasts multiple seasons, and unlike most existing products on the market today, Dolphin II and N4 do not contain any biocides and are environmentally friendly. Dolphin and N4 are designed to meet the requirements of the recently passed legislation in the U.S. House that supports a transition to copper-free anti-fouling marine coatings by 2028.

Naval vessels typically have drydock maintenance schedules that are on multi-year cycles, making AST’s copper-free anti-fouling technology the only foul release coating that has third-party testing data showing superior performance to Hempel’s X3 and Akzo Nobel’s BRA-640 or 1100SR.

“With this new 53-month data, we are able to showcase that our anti-fouling technology outperforms the competition on a timeframe can meet the consumer expectation of a multi-year lifecycle,” said Grant Tremelling, CEO of Adaptive Surface Technologies. “We are excited to be able to release this new positive data closely following the recent legislation that calls for naval vessels transition from copper-based antifouling coatings by 2028.”

This testing has been underway since 2019 and is conducted by an independent third party at the National University of Singapore (NUS). During testing, AST’s coatings are compared with multiple market-leading foul-release coatings. Every month, half the panel is washed with a low pressure (50 psi) waterjet designed to simulate the motion of a boat. All of AST’s coatings performed better than the commercial controls at 18-, 44-, and now 53- month checkpoints, under these dynamic conditions.

For more information on AST’s full suite of products, please visit https://adaptivesurface.tech/

About Adaptive Surface Technologies

A world leader in repellent surfaces, Adaptive Surface Technologies, Inc. is an industrial technology company that produces additives and coatings used for a wide range of industrial, marine, and packaging applications. AST has been backed by Akzo Nobel, Tokyo Electron Ventures, BASF Ventures, Anzu Partners, and other strategic and financial investors. Research and development for AST has been funded by the Office of Naval Research (ONR) and the Air Force Research Laboratory (AFRL), and AST has served as a subcontractor for General Dynamics Electric Boat.

For more information, visit https://adaptivesurface.tech

Press Contacts

Media

Kalyn Schieffer

kos@anzupartners.com

Corporate

Grant Tremelling

grant@adaptivesurface.tech